When it comes to industrial applications, reliable performance is non-negotiable. One key component to achieving this is the use of Rubber Extrusions. These extruded products offer a wide range of benefits and can be tailored to suit various needs. In this article, we’ll explore the world of Rubber Extrusions, how they contribute to reliable performance, and why they’re an essential aspect of many industries.

Table of Contents

1. What are Rubber Extrusions?

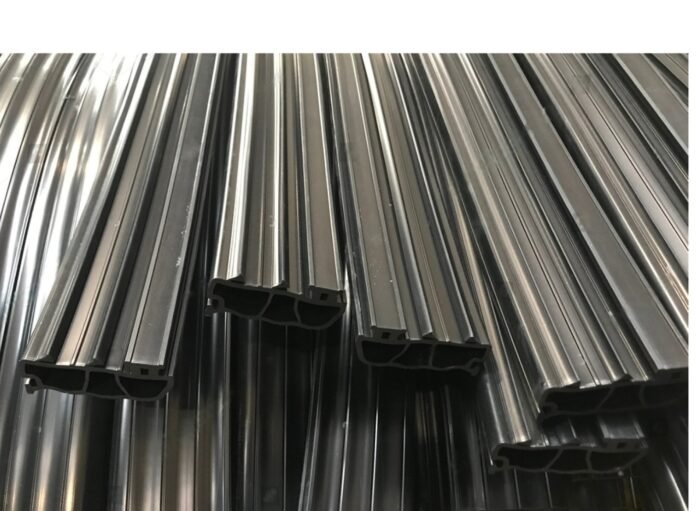

Rubber Extrusions are rubber products that are manufactured through a process called extrusion. This involves forcing a raw rubber material through a shaped die, which ultimately results in a continuous length of rubber with a specific cross-sectional profile. These extruded products can be designed to meet specific requirements and can be used in a wide variety of applications. Some common examples of Rubber Extrusions include rubber seals, extruded rubber gaskets, and weatherstripping.

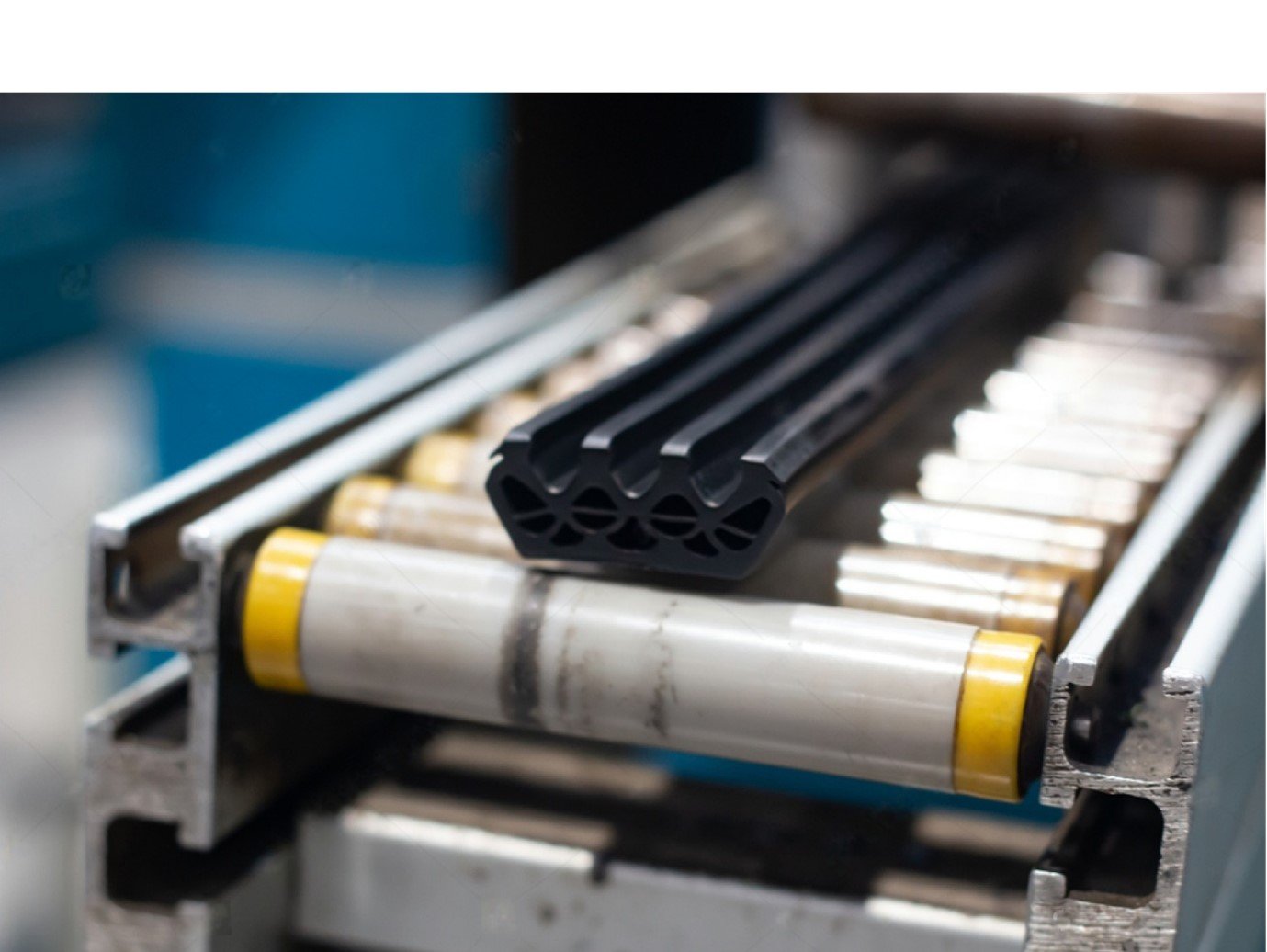

2. The Rubber Extrusion Process

The rubber extrusion process begins with selecting the appropriate rubber compound based on the desired end product’s specific requirements. This compound is then heated and mixed to achieve a uniform consistency. The rubber is then forced through the extrusion die, which is a custom-designed tool that shapes the rubber into the desired profile. As the rubber exits the die, it is cooled and vulcanized or cured to maintain its shape and achieve the desired physical properties. The extruded rubber product is then cut to length, packaged, and shipped to the end user.

3. Common Extrusion Materials

There is a wide variety of rubber materials available for use in Rubber Extrusions. Some of the most common materials include:

- Natural rubber: Offers excellent flexibility, tensile strength, and abrasion resistance. Ideal for use in applications where high levels of stress or wear are expected.

- Silicone: Highly resistant to extreme temperatures and UV exposure, making it suitable for outdoor applications or those involving high heat or cold.

- EPDM: Exhibits excellent resistance to ozone, weathering, and water, making it a popular choice for outdoor applications such as weatherstripping and seals.

- Neoprene: Provides good resistance to oil, chemicals, and flame, making it suitable for use in industrial settings.

- Nitrile: Offers excellent resistance to oil and solvents, making it ideal for applications involving exposure to petroleum products.

- Viton: Known for its exceptional chemical resistance, particularly to acids, fuels, and oils.

4. Benefits of Rubber Extrusions

Rubber Extrusions offer several advantages over other sealing and gasket solutions, including:

- Customizable: Rubber extrusions can be designed to meet specific requirements, ensuring a precise fit and optimal performance.

- Cost effective: The extrusion process is often more cost-effective than other manufacturing methods, particularly when producing large quantities of a specific product.

- Durable: Rubber extrusions are designed to withstand harsh environments and provide long-lasting performance.

- Versatile: With a wide variety of materials and profiles available, rubber extrusions can be used in a diverse range of applications.

5. Applications of Rubber Extrusion Profiles

Rubber Extrusions can be found in various industries and applications, including:

- Automotive: Rubber seals, weatherstripping, and gaskets are essential components in vehicles, ensuring a comfortable, quiet, and efficient ride.

- Construction: Extruded rubber products are used in window and door seals, expansion joints, and waterproofing applications.

- Aerospace: Rubber Extrusions are used in sealing and gasket applications within aircraft, ensuring a safe and efficient operation.

- Medical: Extruded rubber components are used in medical devices and equipment, providing reliable performance in sensitive environments.

- Marine: Rubber extrusions are used in various marine applications, such as seals, gaskets, and hoses, providing durable performance in harsh conditions.

6. Choosing the Right Rubber Extrusion Manufacturer

When selecting a rubber extrusion manufacturer, it’s essential to consider several factors, including:

- Experience: Look for a manufacturer with a proven track record of delivering high quality Rubber Extrusions.

- Capabilities: Ensure the manufacturer can work with the specific rubber material required for your application and can produce the desired profile.

- Quality control: A reputable manufacturer will have strict quality control procedures in place to ensure consistent, reliable products.

- Customer service: Choose a manufacturer that prioritizes customer satisfaction and is willing to work with you to meet your unique needs.

Conclusion

Rubber Extrusions play a critical role in ensuring reliable performance across a wide range of industries and applications. By understanding the rubber extrusion process, the various materials available, and the benefits of Rubber Extrusions, you can make informed decisions regarding your sealing and gasket needs. When selecting a rubber extrusion manufacturer, be sure to consider their experience, capabilities, quality control procedures, and commitment to customer satisfaction. By doing so, you can ensure that your Rubber Extrusions will provide the durability, versatility, and reliability required for your specific application.